FILMAX Sub page

To meet customer needs

We provide pro-active & continuous service

Quick menu

Gallery

BOPP

Biaxially Oriented PolyPropylene

- Transparent film

- Thermal adhesive film

- Synthetic paper

- Functional film

- RETORT

- Electronic protection film

- For cup noodles

- Bundle packing

- For snack and food packaging

- PVDC coated film

- ACRYLIC Coated Film

- Functional Coating Film

- For general printing and laminating

- For textile wrapping

- For tape

- Paper Lamination

- For single-sided, double-sided low-temperature thermal bonding

- Tobacco packing

- White Opaque

- IML

- For anti-fog function

- Heat resistance

- Semi Retort

- High Retort

- Colored Retort

- Protecting prism sheet

- Protecting light guide plate

- For cup noodles

- Bundle packing

- PVDC coated film

- ACRYLIC Coated Film

- Functional Coating Film

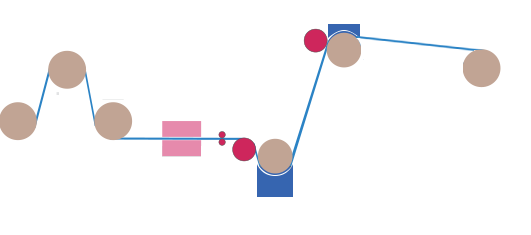

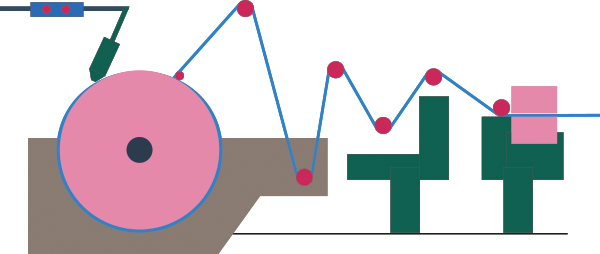

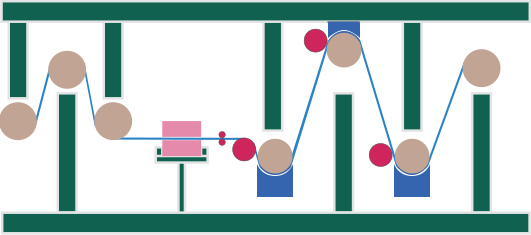

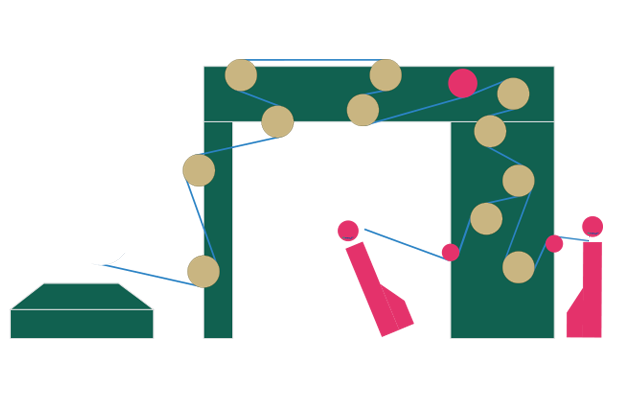

BOPP - Process

1. Extruder

It is a process to melt, knead, disperse and uniformly supply resin as raw material of film.

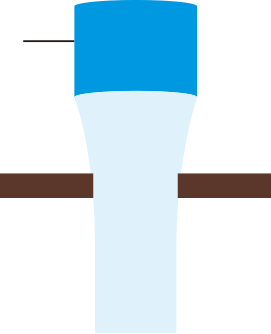

2. Casting

It is a process of cooling molten resin discharged from T-die and solidifying it into sheet form.

3. M.D.O

It is composed of preheating section and stretching section. After heat is applied to the cold-hardened sheet, it is a process of stretching in the machine direction using the difference in speed between rolls.

4. T.D.O

MD The process of stretching the stretched sheet in the transverse direction inside the tenter using a clip. It is subjected to preheating, stretching, heat treatment, and cooling.

5. P.R.S

It is the process of winding the stretched film in the form of a fabric by applying the surface treatment of the film to make it possible to print and adhere.

6. Winder

It is the process of winding the stretched film in the form of a fabric by applying the surface treatment of the film to make it possible to print and adhere.

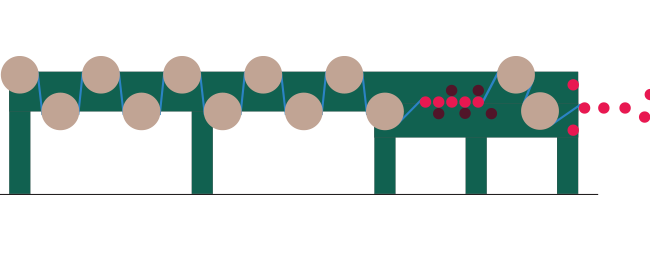

7. Rack

Stabilizes the film formed by stretching, stores it in a rack for a certain time so that the effect of the additive can be stably displayed, cuts it into a standard required by the customer, and packages it into a product.

8. Slitter

Stabilizes the film formed by stretching, stores it in a rack for a certain time so that the effect of the additive can be stably displayed, cuts it into a standard required by the customer, and packages it into a product.

- Extruder

- Casting

- M.D.O

- T.D.O

- P.R.S

- Winder

- Rack

- Slitter

Prev

Prev Next

Next